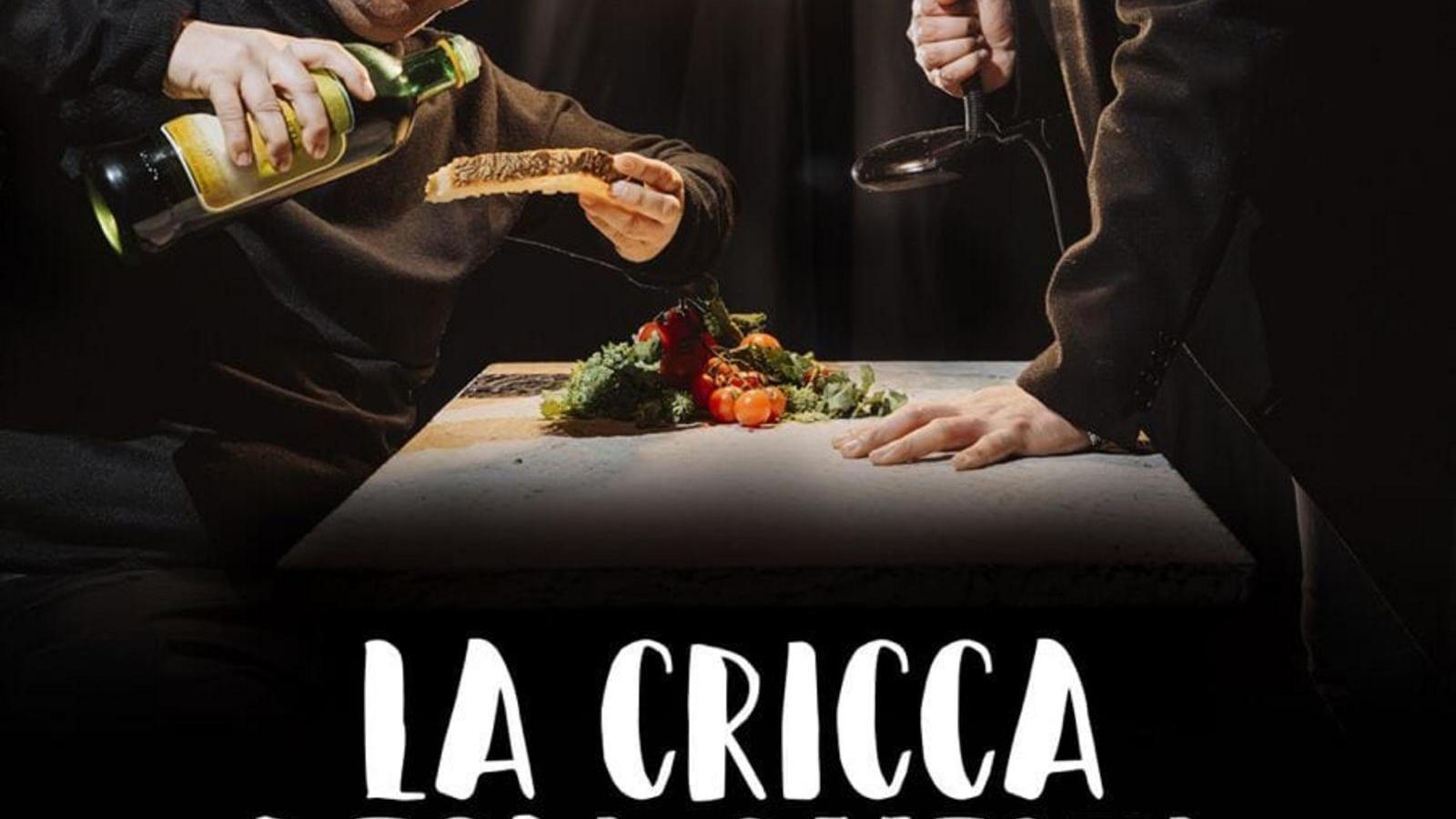

Frantoio Cannone - Dal 1920

From 1920 to today, many things have changed for Frantoio Cannone. We have moved from historic millstones to mechanics.

The Company

From 1920 to today, many things have changed for Frantoio Cannone. We have moved from historic millstones to mechanics. In fact, starting in the ’50s, his grandfather Saverio already began to introduce important innovations inside the mill: the electric motor-driven millstone, for example, and the automatic dispenser for mechanically filling the taxes, on which to place the olive paste for pressing. A major technological renewal that continues in the years up to 2011, the year of change.

With the new market demands, in fact, the persevering father Giovanni decides to turn one of his dreams into reality by moving the entire olive oil mill from the historic center to the outskirts, creating a completely new structure in the heart of Andria's olive growing.

The fourth generation of the olive press saw Francesco Saverio take center stage with his decision to expand the farm by purchasing new olive groves and supporting his father within the company by introducing significant changes in technological innovation, taking the mill to the next step through avant-garde olive processing solutions.

Today, with the use of new closed-loop technology, the millstone is no longer used, replaced by a crusher that crushes the olives and transforms them into pasta that, passing inside closed malaxers, prevents contact with air and therefore the oxidation of the product. An extremely important phase since, carried out in the right time and maintaining the temperature around 26°, it allows the extraction by centrifugal force with an extraordinary result: extra virgin olive oil of the highest quality.

.png)