The Company

How the Olii Santoro brand was born

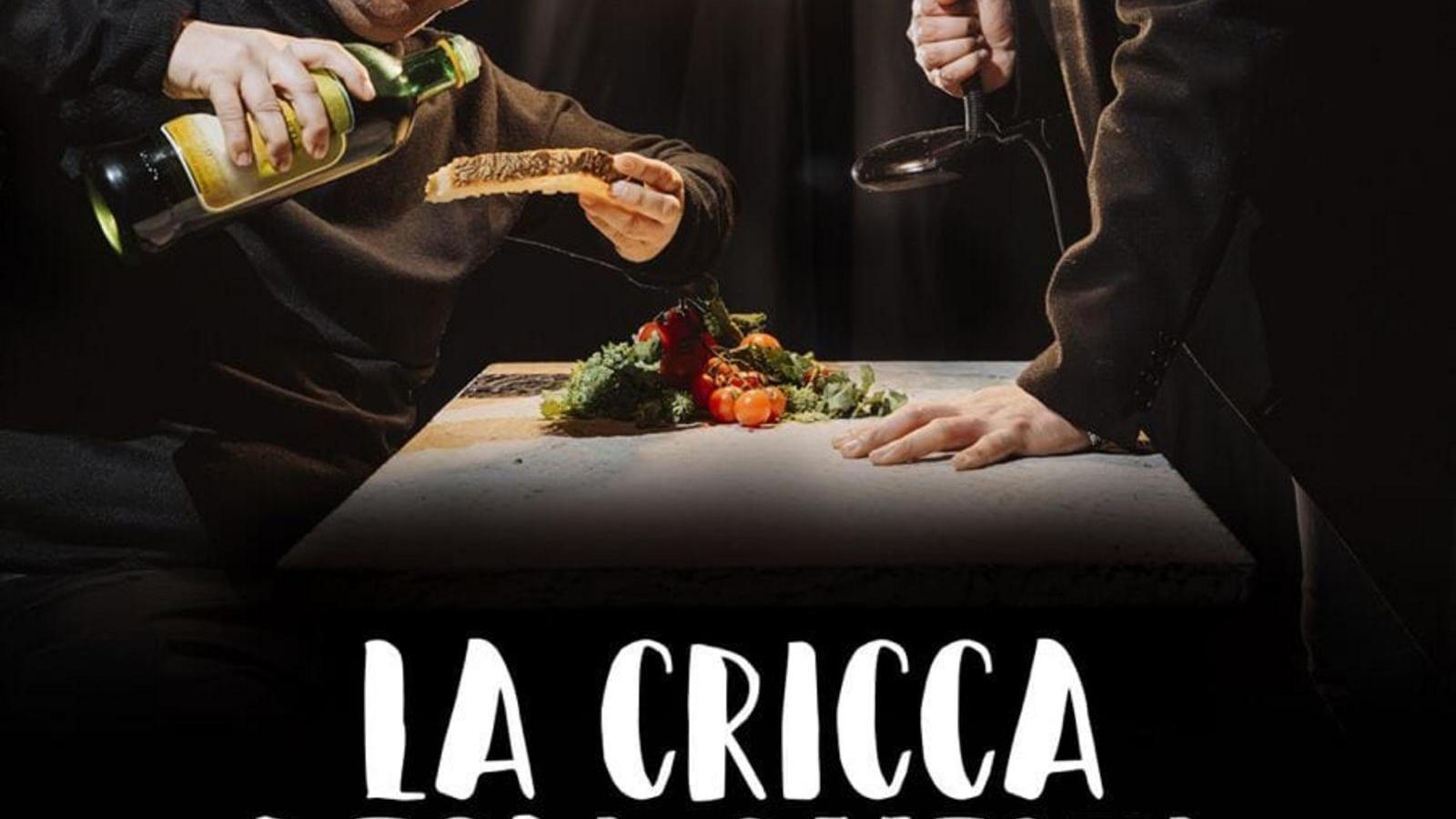

The Santoro company's roots are in Andria, declared “City of Oil” for its well-known olive oil vocation, and date back to the early twentieth century, when Grandpa Vincenzo started the olive oil mill business. Today we are in the third generation. The combination of tradition and modernity allows us to guarantee the best quality in the production of 100% Italian extra virgin olive oil, natural and genuine.

Extraction from cold pressing, only through mechanical processes, within 24 hours of harvesting healthy olives of the right degree of ripeness of the Coratina variety, allows the product to preserve all the natural substances contained in the fruit and very high quantities of healthy polyphenols, with a very low degree of acidity and an authentic and traditional natural taste.

Santoro DOP, PGI and ORGANIC oils are obtained from the first cold pressing of olives, carefully chosen fresh and healthy, harvested with the right degree of ripeness.

A choice that gives the oil more harmonious and balanced aromas, attesting to an excellence that does not require the addition of processes or chemical substances.

The olive press is a place where tradition and technique are constantly balanced, so that each batch of olives produces a genuine, quality oil.

Santoro oils are obtained from the first cold pressing in very modern continuous cycle plants grafted to traditional systems. Particular care is taken in choosing fresh, healthy olives of excellent quality, harvested with the right degree of ripeness.

After harvesting by hand or with the aid of pneumatic dazzlers, the olives are transported to the mill, stored in aerated environments and processed as soon as possible, so as to prevent maceration and oxidation phenomena from being triggered. Extraction begins with a leaf stripper that cleans the olive mass of organic residues such as leaves, twigs, and soil, then moves on to a millstone or hammer crusher, which produces the oily must, which is then sent to the malaxers. In this processing step, a slow and continuous mixing at an optimum temperature of 25° – 27° C, activates the natural enzymes present in the olive paste, to allow the oil droplets to agglomerate into larger, separable drops. In a horizontal-axis separator called a decanter, the liquid part (oil and vegetation water) is separated by centrifugation from the solid part due to the residues from olive processing (pomace). Finally, we move on to the final extraction using a vertical separator that manages to separate the vegetation water from the oil.

Bottling and quality control

In the production of our DOP, PGI and ORGANIC extra virgin oil, storage takes place in vitrified underground tanks and in stainless steel silos, appropriately decanted, to ensure the preservation and maintenance over time of all the qualitative characteristics of the product.

Once the rigorous chemical-physical tests required by law have been passed, the oils are filtered, which allows the nutraceutical and organoleptic properties to be preserved. In fact, extra virgin olive oil acquires better stability and better resistance to aging by separating it from water droplets and impurities through filtration.

Technical checks are performed along the entire production line (filling, capping, labeling, etc.) and on the final product that has arrived in stock, to comply with the provisions of the HACCP self-checking manual. The final product is constantly evaluated with chemical-physical analyses and panel tests (tasting tests) to ensure the quality of the product, which will subsequently be sold to private individuals and large-scale retailers.

Eco-sustainability

With a view to environmental sustainability, the mill uses a photovoltaic system for electricity production and large storage tanks for wet pomace, by-products found from olive processing, which are then used for biomass plants for green energy production.