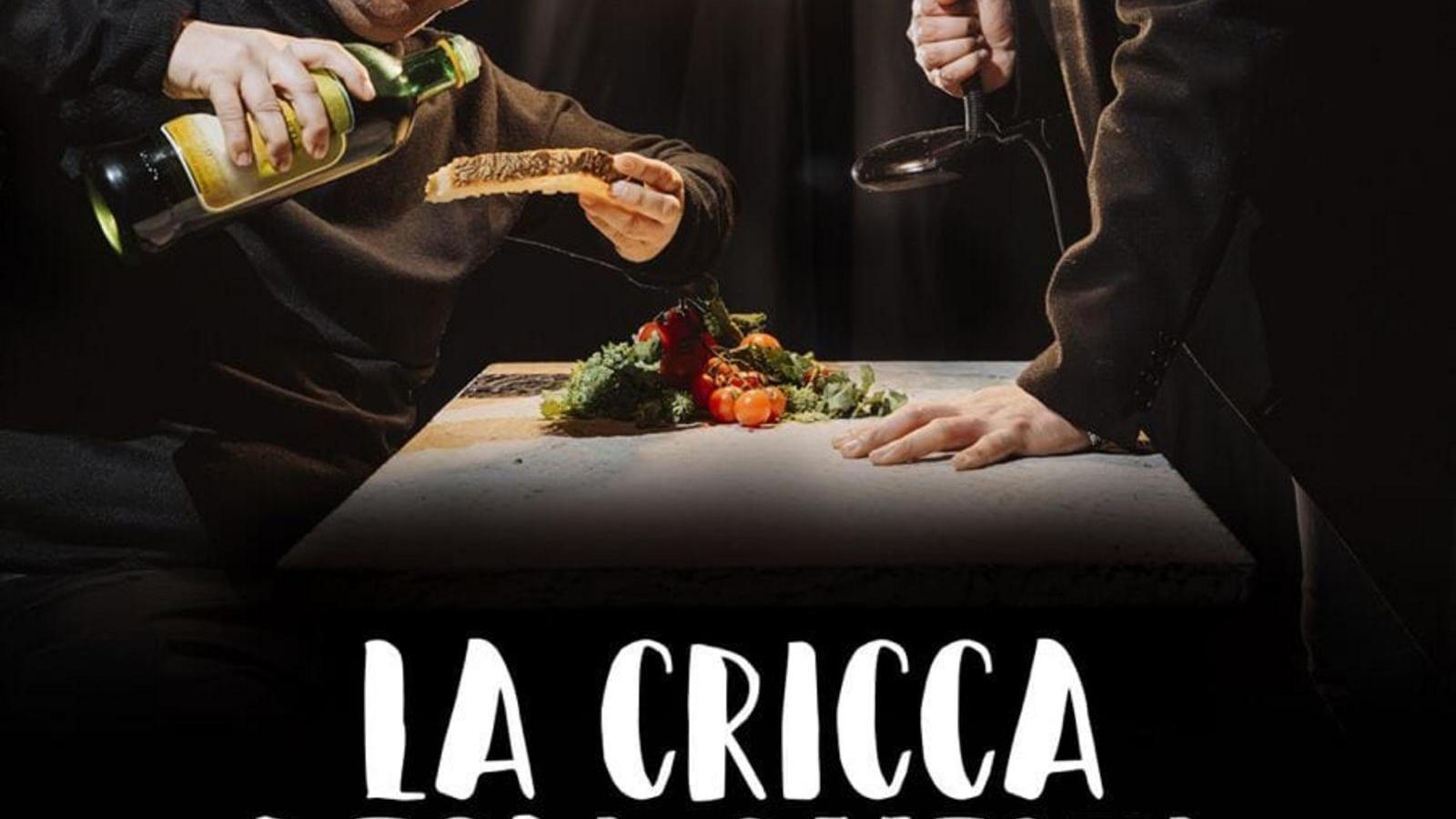

The Company

The Iaculli family, remaining faithful to traditional methods, takes care of the production of their oil, known as the "gold of Puglia," using the same techniques used 50 years ago but with the addition of some evident technological innovations within the company.

In Iaculli's extra virgin olive oil, the noblest traditions of this land, Puglia, come to life. The olives, perfectly ripe, never touch the ground as they are harvested from ancient trees by secure and swift hands. Once harvested, they are immediately taken to the mill where they are sorted, defoliated, and then undergo cold pressing. This process preserves the treasure of Mediterranean aromas, guaranteeing a high standard of quality.

After being separated from the vegetation water, the precious liquid is gravity filtered to obtain a more delicate product with a slight almond aftertaste, perfect for those who appreciate a bold flavor.

The oil is then stored in underground tanks, as deep as five meters, where it quietly matures in the darkness at a constant temperature.

After thorough chemical analysis and a "panel test," the oil is bottled for a selected and increasingly loyal clientele. In this ancient craft, the art of cooking merges with passion and professionalism, giving life to a high-quality product like Iaculli extra virgin olive oil.

Stages of olive processing:

Entry of olives to the mill:

The olives, stored in ventilated bins (for a maximum of 24 hours), are then transported to the defoliating machine where they undergo a dry cleaning process to remove branches, leaves, and soil. They are then washed to ensure consumer safety.

Extraction:

The processing phase initially uses an "auger" that transports the olives to the knife crusher. It's important to emphasize that the crusher slices the olives. The main innovation lies in using a rotor with knives that, through their cutting action, preserves the organoleptic properties of the resulting olive paste, ensuring a distinct fruity scent in our extra virgin olive oil.

Malaxation:

Malaxation is an operation that follows the crushing process and aims to break the emulsion between water and oil, causing oil micelles to merge into larger droplets that tend to separate naturally from the water. The Emotion malaxer meets various needs, including processing for both self-production and third-party contracts. It allows the insertion of the third party's name, visible in real-time throughout the processing on a display, as well as the temperature of the paste. The malaxers are constantly kept below 27°C. Additionally, we use the malaxer without heating in November when temperatures are still mild.

Decantation:

The decanter separates the three components present in the olive paste, each characterized by a different specific weight and therefore separable by centrifugal force: oil, vegetation water, and pomace. This operation has allowed our company to participate in the circular economy and the green economy. In fact, our company fuels the boiler with the pomace and subsequently uses the wastewater for agronomic purposes.

Lastly, but not of lesser importance, we use the discarded olive leaves as feed for sheep and goats. The olive must is conveyed to the centrifugal separator, designed to remove water and other impurities from the olive oil. Specifically, the machine separates the pomace (olive pulp) from the olive stones.

Separation:

The olive must is conveyed to the centrifugal separator, designed to remove water and other impurities from the olive oil. Specifically, the machine separates the olive stones from the pomace.

Storage:

The oil is stored in underground tanks, as deep as five meters, where it quietly matures in the darkness at a constant temperature. After undergoing evaluation by an accredited panel test committee, it is classified and bottled.

Bottling:

The company utilizes a semi-automatic bottling line, tailored to meet market demands.

.png)

.png)

.png)

.png)

.png)

.png)